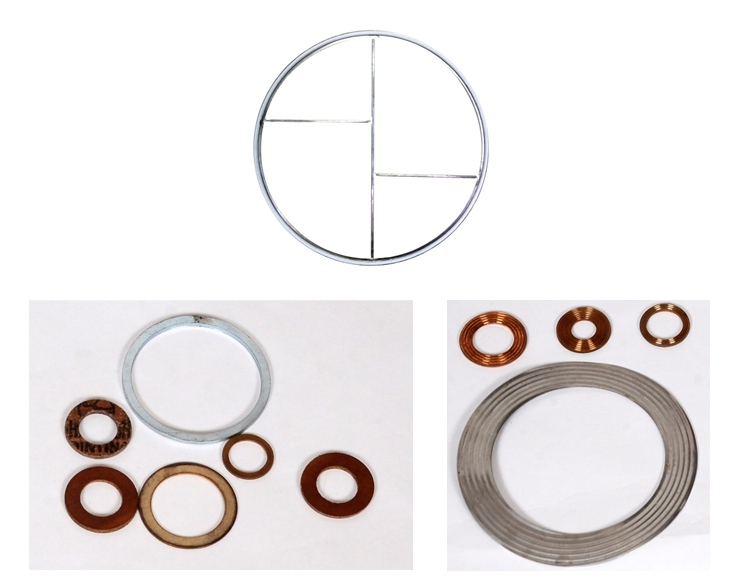

Solid metal Gasket

The Solid material is to use metal, which cannot be punched out of sheets, but are still cheap to produce. These gaskets generally have a much higher level of quality control and can withstand much higher temperatures and pressures.

Spur Corporation is a manufacturer of standard size gaskets, non-standard size and custom gaskets from metal for the petroleum and natural gas industry, Nuclear power plants,power generation, food service,commercial transportation industry as well as pharmaceutical industries. We provide industrial metal, metal clad & composition sheet gaskets for compressors,heat exchangers, condensers, valves, pumps,and general industrial applications in all sizes & shapes and also made customised as per requirement. Solid metal gaskets are used in applications where temperatures and pressures rule out the use of traditional gasket materials.

Flat & Serrated gaskets

Solid metal gasket uses the following material :

- Carbon Steel

- Stainless Steel 304,304L,316,316L,316Ti,321,347,

- Monel® 400

- Inconel® 600,625,800

- Incoloy 800, 825

- Nickel 200

- Titanium

- Hastelloy

Copper specification : As per Customer Requirement. size : As per Customer Requirement.

The following are the various varieties in solid metal gaskets :